The Concept’s extremely efficient powertrain relies on YASA’s innovative axial-flux high-tech electric motor, a third the size and mass of a regular EV motor

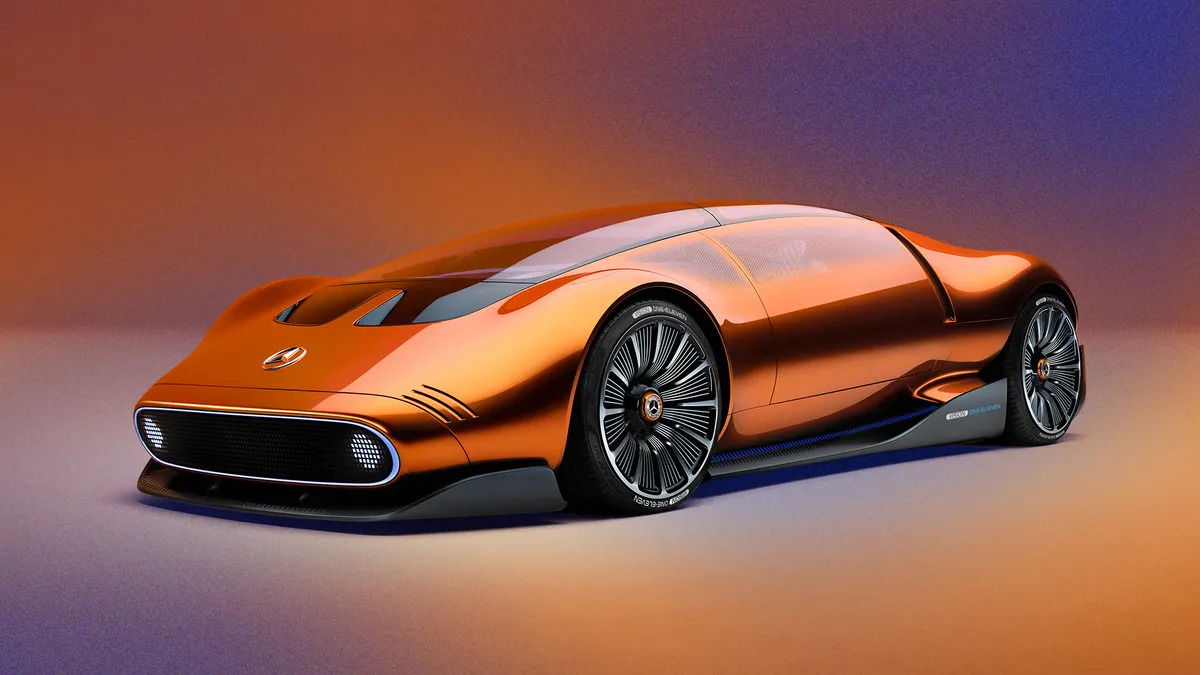

In 1969, just a few months after the first humans landed on the moon, Mercedes-Benz unveiled a groundbreaking concept car at the Frankfurt auto show.

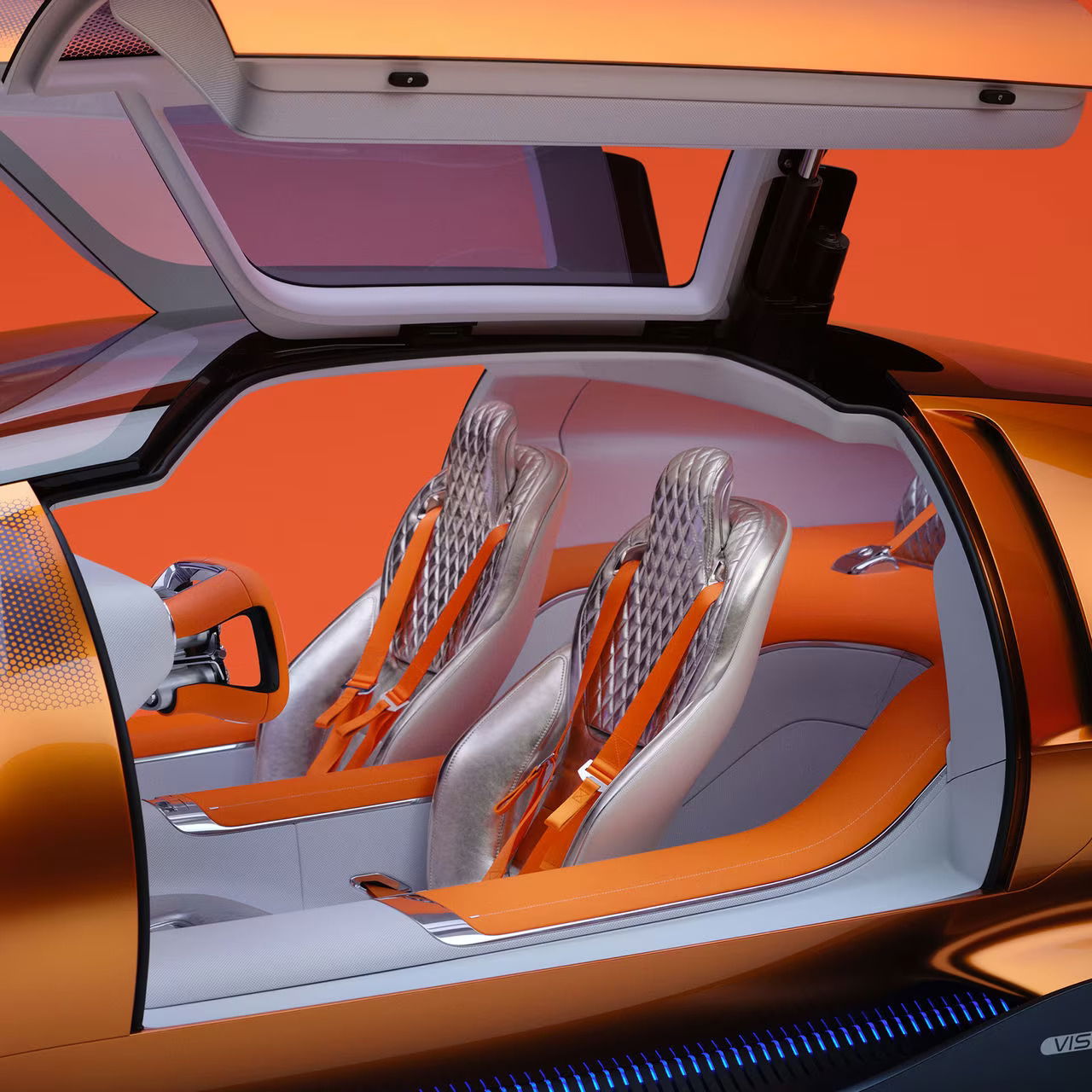

Dubbed the C111, the vehicle was a striking orange-and-black coupe that boasted gullwing doors and served as a test bed for emerging technologies, including a four-rotor Wankel rotary engine.

Fast forward 54 years later and Mercedes-Benz has taken inspiration from that iconic car to create its latest concept vehicle, the Vision One-Eleven.

Like its predecessor, the One-Eleven is orange and showcases new technology, this time utilizing small and lightweight axial flux electric motors.

Although axial flux motors have been used for some time in optical drives, they have yet to find widespread use in automotive applications.

Notable exceptions include the one-of-a-kind Jeep Magneto and hybrid supercars produced by Acura, McLaren, and Ferrari.

Related: The Porsche Mission X: A Spectacular Reinterpretation Of A Lightweight Electric Hypercar

The Italian OEM, which remains unnamed, has been sourcing motors from Yasa, a British company that was acquired by Mercedes in 2021.

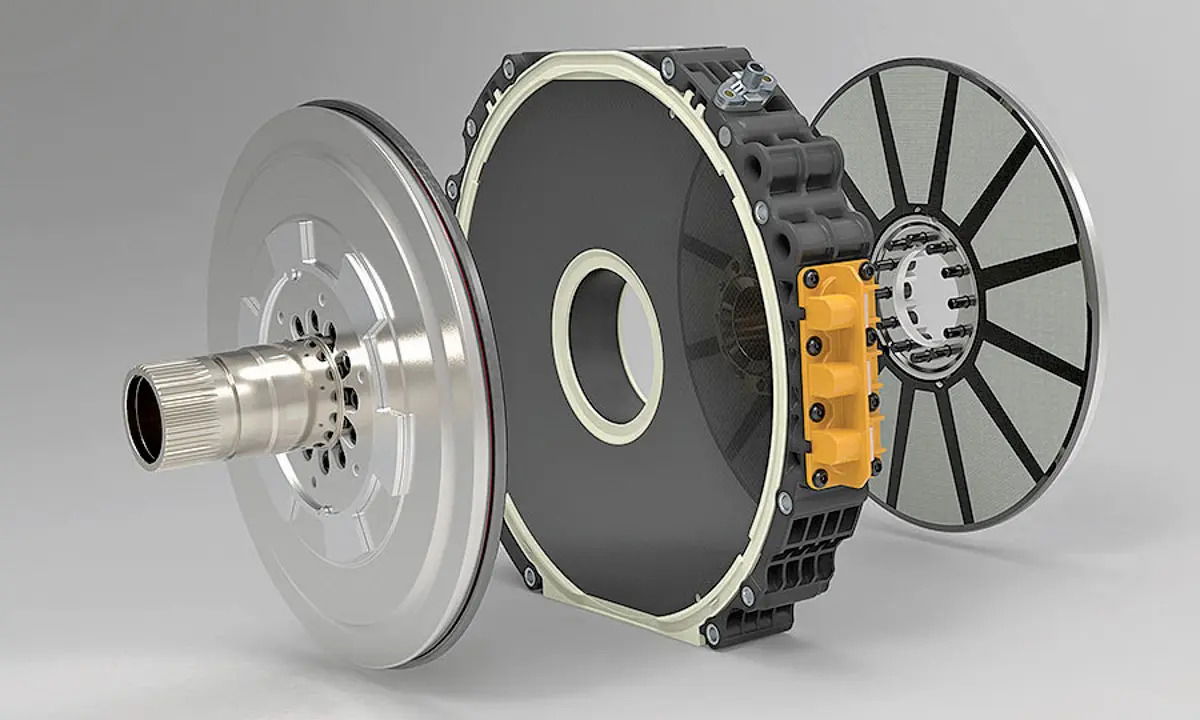

While axial flux motors, like radial flux motors, use permanent magnets, soft iron, copper, and an aluminum housing, the two types differ significantly beyond this point, according to Tim Woolmer, the founder of Yasa.

In a radial flux motor, the flux moves from the permanent magnets to the stator, around the stator yoke, and back into the rotor, forming a loop. The flux in the airgap travels radially, hence the name "radial flux machine."

According to Tim Woolmer, in an axial flux motor with two discs and one stator, the flux travels straight through the stator from rotor to rotor, then around the back steel in the rotor and back again through the stator via a different coil.

Woolmer's PhD work focused on soft magnetic composite material, which is used in Yasa's motor in segments bound in copper coils within the stator.

Woolmer initially chose this approach due to the difficulty of compressing the composite material into large enough pieces for a whole motor stator.

He realized that making a stator in the same way as a radial flux motor would have required a 4,000-ton press, but the smaller pieces only needed 210 tons of pressure. Woolmer considers this realization a eureka moment with enormous advantages.

According to Tim Woolmer, the yokeless and segmented armature design of Yasa's axial flux motors eliminates the need for the stator yoke because the flux flows straight through the stator, around the rotor, and then back through the stator.

This design inspired the company's name. Yasa's axial flux motors are also smaller and lighter than equivalently powerful radial flux motors, with six of them producing a combined output of 1 megawatt in 2015.

This power was sufficient to break the record for climbing Pikes Peak when Rhys Millen used it. The compact design of Yasa's axial flux motors made them an ideal choice for Ferrari, which needed an electric motor small enough to fit between the engine and gearbox of its SF90 hypercar.

The crank height had to be as low as possible for center of gravity reasons, so the motor could only have a 105-millimeter radius.

According to recent news, the Mercedes brand is happy to continue providing Yasa motors to specialized OEMs like Ferrari, but it acquired the company primarily to use its technology for its own purposes. This brings us to the Vision One-Eleven, the car that was designed to experiment and develop new powertrain ideas.

Related: These Are The Top-Ten Cheapest Electric Cars Money Can Buy Right Now

The car only had a limited axial length of around 65 millimeters, which meant that the packaging volume was restricted to about two to two and a half liters.

The new powertrain for the Vision One-Eleven includes an axial flux motor for each of the rear wheels and a battery pack that employs the same chemistry found in Lewis Hamilton's Formula 1 car cells.

The powertrain is expected to be feature-complete, like the hyper-efficient EQXX that was driven last summer. A production version of the concept's powertrain is set to be released in Mercedes' next EV architecture, which will be featured in a cheaper Mercedes EV in 2024.

Mercedes is excited to use Yasa's technology for its own vehicles, but it will continue to supply Yasa motors to specialized OEMs. Mercedes has not yet announced the production of an all-electric sports car, so the ideas presented by the Vision One-Eleven remain in the distant future.

In addition to a high-performance EV powertrain, the concept also features an innovative user interface that incorporates augmented reality.

The Magic Leap headset demonstrated how a 3D map can beam into space from the infotainment screen, and how AR can render parts such as the A pillar or door transparent to the driver, eliminating blind spots.

These ideas are impressive, but their feasibility depends on the maturity of the technology.

While wearing AR goggles in a sports car may be less awkward than in other settings, it may not be necessary as augmented-reality windshields are nearing reality.

According to Konstantin Neiss, who is responsible for the development of Mercedes' electric drive unit, axial flux motors may be integrated into production Mercedes EVs by the end of the decade.

The smaller and more powerful these motors become, the less space they would occupy at the center of the vehicle. Consequently, the freed-up space might be utilized for additional battery or cargo volume.

In fact, the smaller size and mass of the axial flux motor could even enable hub-mounted motors in an EV, which has been a long-awaited development using radial flux motors.